CUTTING-EDGE PROCESSING

TECHNOLOGIES DEVELOPING QUALITY PRODUCTS

We are a leading manufacturer of high quality dehydrated food with cutting-edge technologies offering all types of dried food. Thus, we are not only manage to meet all customer needs, but also to earn their trust.

CUTTING-EDGE PROCESSING

TECHNOLOGIES DEVELOPING QUALITY PRODUCTS

We are a leading manufacturer of high quality dehydrated food with cutting-

edge technologies offering all types of dried food. Thus, we are not only manage

to meet all customer needs, but also to earn their trust.

CUTTING-EDGE PROCESSING

TECHNOLOGIES DEVELOPING QUALITY PRODUCTS

We are a leading manufacturer of high quality dehydrated food with cutting-

edge technologies offering all types of dried food. Thus, we are not only manage

to meet all customer needs, but also to earn their trust.

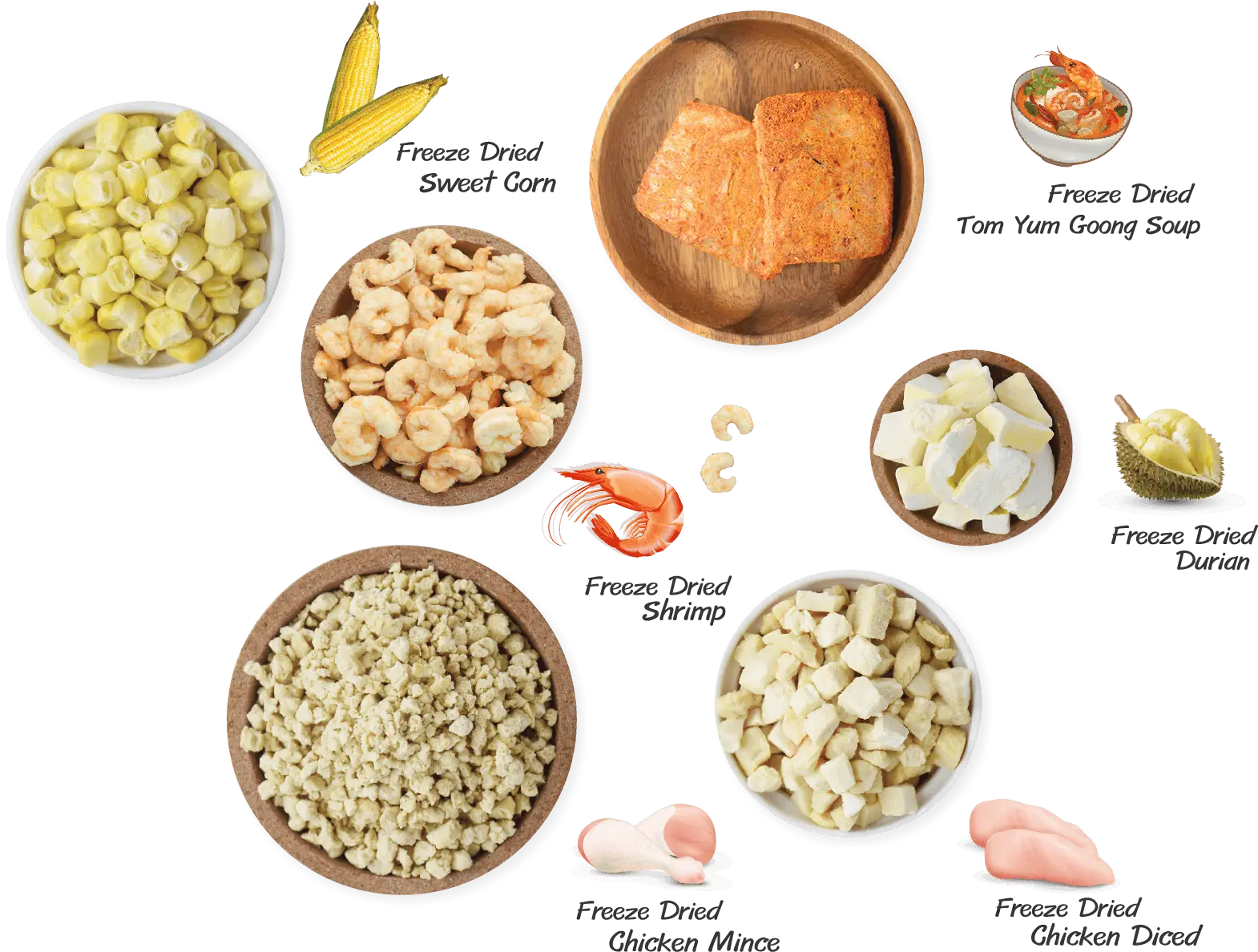

FREEZE DRYING

Freeze drying is the best dehydration process as it can preserve the food freshness for a long time and allow quick recovery of its original shape in hot water. Freeze drying is typically used to preserve perishable products and allow convenient transport. Freeze drying works by freezing products, reducing the atmospheric pressure to make the frozen water sublime, adjusting the pressure back to normal and increasing the temperature. This process can best preserve the flavor, texture, appearance and nutritive value.

Freeze drying is the best dehydration process as it can preserve the food

freshness for a long time and allow quick recovery of its original shape in hot

water. Freeze drying is typically used to preserve perishable products and allow

convenient transport. Freeze drying works by freezing products, reducing the

atmospheric pressure to make the frozen water sublime, adjusting the pressure

back to normal and increasing the temperature. This process can best preserve

the flavor, texture, appearance and nutritive value.

SPRAY DRYING

Spray drying is a dehydration process for liquid food. It works by spraying the liquid

food through a nozzle into a drying chamber. Upon coming in contact with hot air in the

chamber, the water content in the food rapidly evaporates turning it to soluble powder.

And brief exposure to heat means fewer nutrient losses.

Spray drying is a dehydration process for liquid food. It works by spraying the liquid food through a nozzle into a drying chamber. Upon coming in contact with hot air in the chamber, the water content in the food rapidly evaporates turning it to soluble powder. And brief exposure to heat means fewer nutrient losses.

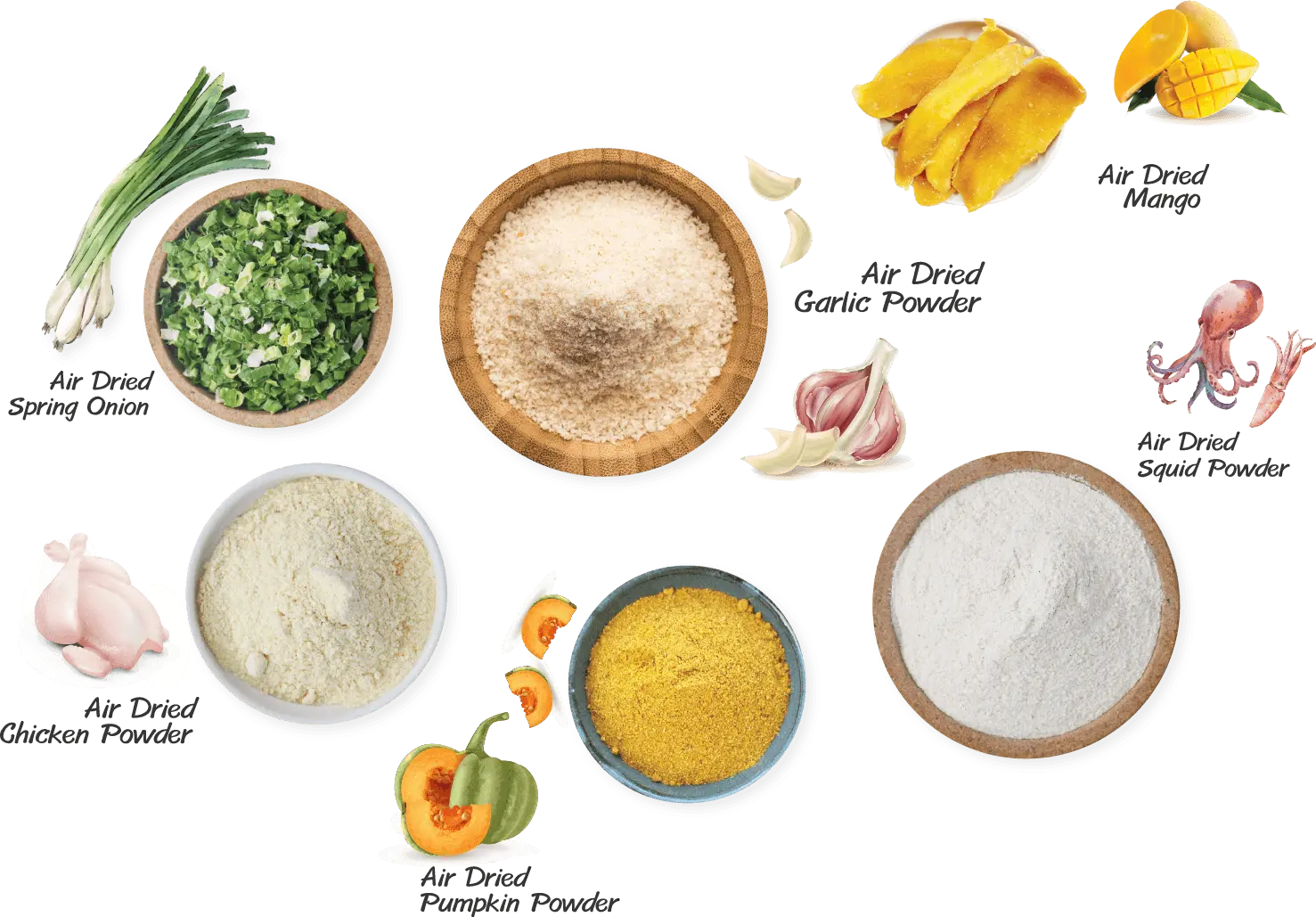

AIR DRYING

Air drying is a traditional dehydration process that uses hot air to evaporate water content of product. Air drying is one of the most popular food preservation methods as it offers unique texture and flavor, simple dehydration procedure and low cost.

Air drying is a traditional dehydration process that uses hot air to evaporate water

content of product. Air drying is one of the most popular food preservation methods

as it offers unique texture and flavor, simple dehydration procedure and low cost.

DRUM DRYING

Drum drying is dehydration processes used to make flakes which can be ground into soluble powder resemble to spray dried products with fiber retained. This method is suitable for making healthy food that should retain texture and fiber after defrosting.

A drum dryer consists of 1 or 2 hollow cylinder(s) heated by vapor or electric power,

a liquid feeding system which applies a thin layer of viscous liquid to the hot drum surface to evaporate the water content, and a scraper blade which scrapes out thin layer of dried material.

Drum drying is dehydration processes used to make flakes which can be ground into

soluble powder resemble to spray dried products with fiber retained. This method is

suitable for making healthy food that should retain texture and fiber after defrosting.

A drum dryer consists of 1 or 2 hollow cylinder(s) heated by vapor or electric power,

a liquid feeding system which applies a thin layer of viscous liquid to the hot drum

surface to evaporate the water content, and a scraper blade which scrapes out thin

layer of dried material.

SWEET CORN POWDER

PUMPKIN POWDER

POTATO POWDER

SWEET POTATO POWDER

BANANA POWDER

CEREAL POWDER

FROZEN

Individual quick freezing (IQF) is the latest freezing technology. This advanced technology allows the long-term preservation of freshness of fruits and vegetables by briefly freezing the products at low temperature (-30°C to – 40°C) giving good quality products that are thoroughly and evenly iced without clustering.

Individual quick freezing (IQF) is the latest freezing technology. This advanced

technology allows the long-term preservation of freshness of fruits and vegetables by

briefly freezing the products at low temperature (-30°C to – 40°C) giving good quality

products that are thoroughly and evenly iced without clustering.

EXTRACTION

Extracts are products that subject to two processing processes. The first process is to extract nutrients or small particles from raw materials using water or other liquid.

The second process is to evaporate water or liquid to obtain the concentration that is suitable for use and convenient for transportation. We have a highly effective extraction technology which allows the mass production and the manufacture of healthy food extracts (e.g. Concentrated Chicken Soup) and other extracts to use as raw materials for spray drying and other processes.

Extracts are products that subject to two processing processes. The first process is

to extract nutrients or small particles from raw materials using water or other liquid.

The second process is to evaporate water or liquid to obtain the concentration that is

suitable for use and convenient for transportation. We have a highly effective

extraction technology which allows the mass production and the manufacture of

healthy food extracts (e.g. Concentrated Chicken Soup) and other extracts to use as

raw materials for spray drying and other processes.